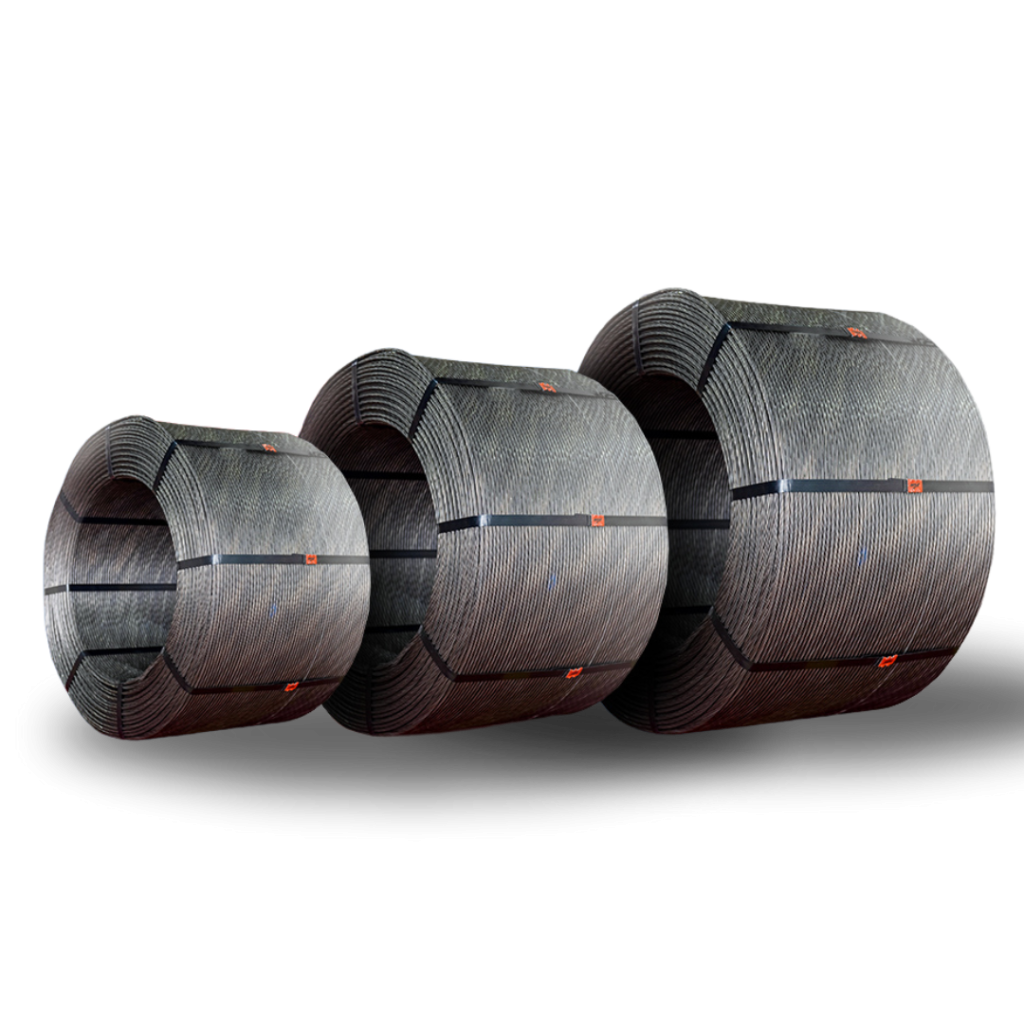

LRPC PT Strands

At ASD, our goal is to actively and continuously create products of the highest calibre in order to accelerate the growth of the country. It has taken this approach by introducing the cutting-edge Low Relaxation Prestressed Concrete Strands (LRPC). These strands are extremely dependable and are intended to support and quicken the current and future infrastructure and building projects in India and around the world.These strands are extremely trustworthy and designed to withstand pressure and perform at their best in demanding settings and circumstances in a variety of industries. They follow both international and Indian norms, resulting in years and years of impressive performance.

PRODUCT QUALITY

At ASD, we use cutting-edge steelmaking technologies, contemporary gear and plant, high-end testing apparatus, and the best process controls. Our 1.4 lakh MT annual manufacturing capability enables us to produce premium wire rods that are ideal for demanding and premium applications.

We employ cutting edge technologies in the production of LRPC strands. Our wire rod mills are among the few in the world, the best in their class, and well ahead of the competition. These excellent wire rods enable the creation of remarkable LRPC strands, which provide our clients in the construction industry with reliable performance.

For our wire facility, we have a NABL-accredited test laboratory, an ISO certificate, and a BIS. For our domestic and international clients, we produce LRPC strands in diameters of 3/8-inch, 1/2-inch, and 5/8-inch in accordance with IS14268:2017, BS5896, EN10138, ASTM A 416/A, 416 M, AS/NZS 4672, and other standards.

PRODUCT QUALITY

WHY LRPC STRANDS?

It possesses low-stress relaxation loss at normal and higher temperatures in comparison to typical steels.

Latest technology for manufacturing LRPC strands.

strict quality and process controls throughout the whole manufacturing process.

Modern electrical and electronic controls to help find and eliminate any deviations more effectively.

Prestressed concrete strands can be used to build larger spans up to 25–30 metres.

increased resilience to fatigue.

Pickling line, multi-block wire drawing, and stranding are automated and sophisticated processes.

High reliability can be achieved by building lighter buildings.

ASD METAL

CORE VALUES

Superiority

We are committed to achieving excellence in all aspects of our business, striving for the highest standards of quality and performance.

Dependability

Our customers rely on us to deliver on our promises consistently. We take pride in being a dependable partner, ensuring reliability in every interaction.

High-Quality Partnership

We believe in fostering strong and enduring partnerships built on trust, transparency, and mutual respect. Our dedication to cultivating high-quality relationships is paramount to our success.

Pay Attention

Attention to detail is ingrained in our ethos. We meticulously focus on every aspect of our operations to ensure precision and accuracy in all that we do.

Inventiveness

Innovation drives us forward. We embrace creativity and ingenuity, constantly seeking new solutions and approaches to meet the evolving needs of our customers and industry.